Degassing MDU-RBS units are equipped with pumps RBS. RBS is an innovative rotary volume blower with special profile lobes, which jointly with a new configuration LOW-PULSE system, reduces the residual pulsations of the injected gas pressure to the level less than 2% of the operating pressure. Extended shafts allow a higher operating pressure (absolute pressure 2000 mbar) and higher rotation speed.

RBS pumps have a high capacity - up to 25,000 m3/h with working pressure up to 500 mbar.

Bearings with solid and reinforced case, calculated on a theoretical life time of 100,000 hours under the most adverse conditions, the absence of friction parts in the working area of the pump, application of anti-corrosion, anti-static, abrasion-resistant cover provide an increased operating life of the unit.

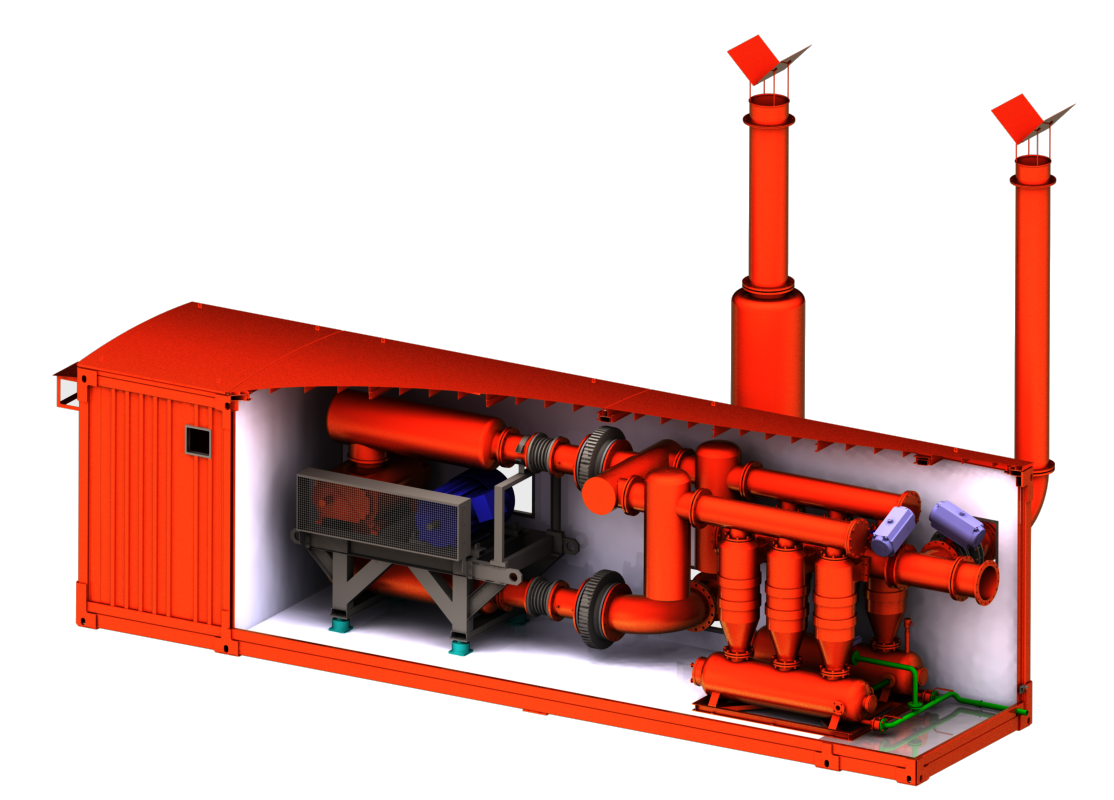

Also, to ensure heightened security and to increase the life time of pump groups and elements of the unit, each MDU-RBS is completed with purification system of methane-air mixture from mechanical impurities and moisture, placed in a separate module, installed before vacuuming modules of MDU.

The purification system of methane-air mixture includes separators and filters of stainless steel. Draining of separators is automated.

Degassing unit type MDU-RBS is fully adapted to the Russian market and their technical specifications has no analogues in the modern industry.

Typical delivery degassing unit MDU-RBS includes 2 modules:

Additionally, according to customer's specifications, degassing unit can be equipped with:

The possibility of using modular degassing units of the type MDU as gas suction units (GSU).

LLC “RDE “Factory of MDU” specifically for gas controlling on the excavation site has developed a new model of degassing module, which is fully comply with both the current version of “Instructions for the degassing of coal mines” and the current version of “Instructions for use the schemes of airing of excavation areas of mines with isolated removal of methane from out space using gas-suction units (GSU)”.

The advantage of the new module is that it is combination of pump group (on the basis of the vacuum pump RBS 155 with capacity to 185 m3/min produced by Italian factory ROBUSCHI), purifying system (produced by ROBUSCHI), isolation and relief valves and gas analyzing equipment.

Gas analyzing equipment is used in automatic mode for controlling the concentration of methane, oxygen and carbon monoxide in pumped gas mixture that gives the opportunity to prevent the occurrence of endogenous heating of coal at an early stage. In accordance with the current version of «Instructions for use the schemes of airing…» GSU consists of working and backup units with equal capacity.

Another advantage of the new module is the lack of a large number of elbow bends and tee bends, creating additional resistance. New module connects directly to the main pipeline. The number of modules is limited only by the throughput capacity of the pipeline.